Laser Welding Technology

Benefits of Laser Welding Technology

How Laser Welding Works:

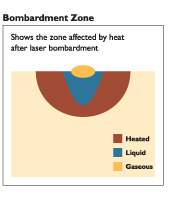

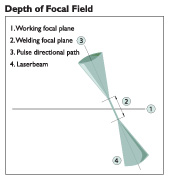

LASER is an acronym for “Light Amplification by the Stimulated Emission of Radiation.” Laser welders produce a sharp, focused light beam that melts a very small area of metal. The benefit of this technology is that very little heat is generated at the weld point, allowing users to easily weld 0,05mm (.002”) away from the most complicated and intricate component parts without damaging heat sensitive materials.

Solid state laser welder operators hold parts in their hands while viewing the application through a stereo-microscope in the welding chamber. An internal cross-hair allows the operator to easily align and weld the parts at the correct location.

The Power of Hot Light

LaserStar Technologies’ development of the “free-moving” concept enable welding laser users to eliminate costly fixturing devices, benefit from pin-point accuracy, increase the range of assembly and repair applications and minimize the potential hazards of heat damage. With a laser welder, the resulting weld is considerably stronger than a traditional solder joint. Manual Laser Welding Systems are ideal for the smallest workshop to large industrial manufacturers. Common industry applications include:

- micro industrial-medical device spot and seam welding assemblies

- electronically compatible voltage sensitive applications

- injection mold repair welding

- jewelry design, production and repair

- dental laboratory partial, crown & bridge, and implant fabrication and repair

- optical eye wear fabrication and repair

Contact LaserStar today to learn more about solid state manual welding systems for your business.